Making the best choice for your thermal label needs

Both methods of on-demand printing offer incredible benefits for those looking to print their own thermal labels. It's important that you have a basic understanding of Thermal Transfer and Direct Thermal, so that you can make the proper choice for your needs.

The difference between Thermal Transfer and Direct Thermal

In simplest terms, Thermal Transfer printing utilizes a thermal ribbon and Direct Thermal printing does not.

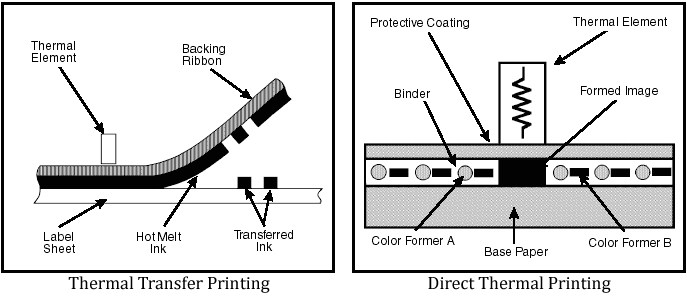

Thermal Transfer: Thermal transfer involves the thermal printhead elements (dots) heating the backside of a thermal transfer ribbon to melt and transfer the compounds on the front side of the ribbon to the label material, thus creating the printed image.

Direct Thermal: Direct Thermal printing requires a heat sensitive paper or film material. The thermal printhead elements come in direct contact with the heat sensitive label material, where the heat from the elements cause a color change in the material to create the printed image.

Comparing Thermal Transfer to Direct Thermal

Thermal Transfer and Direct Thermal each have their areas of best use. Read on to see which is the best fit for you.

Thermal Transfer vs. Direct Thermal: Choosing the best option for your label needs

| Thermal Transfer |

|

| Direct Thermal |

|

Thermal Transfer vs. Direct Thermal: Advantages and Disadvantages of each

| Advantages | Disadvantages | |

|---|---|---|

| Thermal Transfer |

|

|

| Direct Thermal |

|

|

We would like to thank SATO America for the use of their Thermal Transfer vs. Direct Thermal Advantages and Disadvantages table.

Thermal Printhead Life and Cost

Thermal printers have what is called a Printhead or Thermal Element in them, which heats up in order to generate a the printed image. Depending on your type of thermal printer, printheads can range from just over a $100 to upwards of $1,000 dollars to replace. It's important to understand the effect that running Direct Thermal labels can have on your printhead vs. running Thermal Transfer labels.

Direct Thermal: When you are Direct Thermal printing, the material is in direct contact with the printhead, as it is pulled through the thermal printer. Even though most Direct Thermal materials have a coating on them to ease the wear on the printhead, there is still a great deal of abrasive action taking place. Also in Direct Thermal applications, dust and debris that may become present on labels are in direct contact with the printhead. As these foreign materials are pulled across the printhead, they may burn onto the elements or physically damage the elements resulting in poor print quality and/or premature printhead failure.

Thermal Transfer: When Thermal Transfer printing, you are using a thermal ribbon, which acts as a buffer between the printhead and label material. Thermal ribbons are designed with an acrylic back-coating, that serves to increase printhead life, by reducing static and friction.

Due to the situations described above, expected printhead life in direct thermal printing applications is significantly reduced when compared to thermal transfer printing applications. Generally speaking, a company should anticipate direct thermal printheads providing an expected lifetime of 25% - 50% of a thermal transfer printhead.

Thermal Printer Configuration and Cost

Thermal Transfer printers typically have the capability of printing either Thermal Transfer or Direct Thermal labels. If you only going to print Direct Thermal, there are printers available that only have Direct Thermal capability. These printers are generally less costly to purchase because they do not contain any of the hardware necessary for driving and controlling ribbon.

Eliminating the ribbon and ribbon hardware components also results in a less complex printer with fewer parts to wear and/or break, resulting in lower service costs and less downtime over the life of the printer. Additionally, operators don't have to be concerned with ribbon settings or adjustments, leading to improved uptime and increased efficiency.

Hopefully this has provided you with all of the information necessary in order to make the best decision for your thermal printing needs. If you have any other questions, please contact us by sending a message or better yet, just give us a call at (888) 425-3955. We would be delighted to answer any questions you may have.

Request a Quote

No Obligation / No Hassle

Receive a Sample Kit

See Thermal Labels